Eliminate the Interfaces

A little planning goes a long way. The safety and speed of modular supports cannot be denied.

However, the successful implementation of modular supports needs a little more planning than welding. This needs services such as engineering, 3D modeling, material management, installation, laser scanning, and concrete testing.

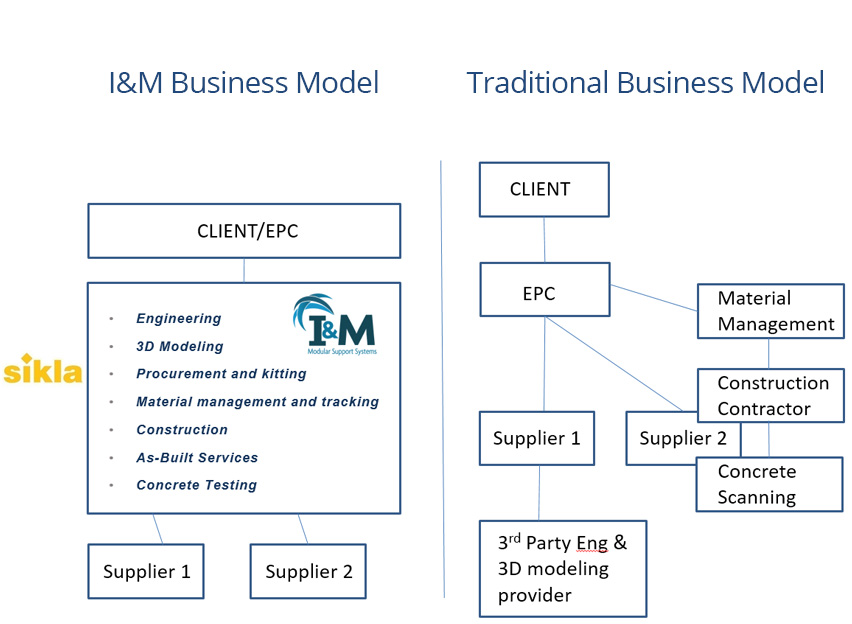

Traditional suppliers of modular supports place themselves between the client and the service provider, resulting in unnecessary interfaces. Even worse, some of these services might not be offered at all and a 3rd party must be inserted into the process. This is inefficient, and frustrating.

I&M’s business model puts the client first.

I&M provides all the required services in-house, giving you direct access to all the services you need, as required.

I&M is the exclusive distributor of Sikla in Canada, which is the most comprehensive line of modular supports in the market. We also use our partnerships to provide material from other modular suppliers, giving you a one-stop shop for modular supports.